Ferrous alloys analysis

Cast and steel control shall be carried out both while smelting and at entrance to metal materials production. Exact and rapid analysis is required in all cases to determine the alloy mark, presence or absence of harmful additives.

Alloy control while smelting helps to control and change if necessary the alloy addition.

Harmful additives in alloys may cause changes in the product property and lead to serious damage.

The X-ray fluorescence method provides determination of elements in the range from Na to U with the concentration range from 0.001-0.01% to 100%. High relative accuracy of determination (0.1-0.3%), high efficiency and rapidness, simple sample preparation lead to wide application of XRF method for ferrous alloys analysis.

Sample preparation consists of flattering the sample surface. The roughness of the surface shall be better than 50 micron, it shall have no cracks, porous or cavities, no slag or nonmetal inclusions.

No further sample preparation is required. The sample is placed into a sample cartridge and then into spectrometer. Analysis is fulfilled automatically with a chosen program and prepared calibration curve.

Small size specimens or irregular shape specimens can be analyzed with fundamental parameters method.(standardless analysis method). In the latter case no calibration samples are required, but the accuracy of analysis is a little bit worse.

Alloy control while smelting helps to control and change if necessary the alloy addition.

Harmful additives in alloys may cause changes in the product property and lead to serious damage.

The X-ray fluorescence method provides determination of elements in the range from Na to U with the concentration range from 0.001-0.01% to 100%. High relative accuracy of determination (0.1-0.3%), high efficiency and rapidness, simple sample preparation lead to wide application of XRF method for ferrous alloys analysis.

Sample preparation consists of flattering the sample surface. The roughness of the surface shall be better than 50 micron, it shall have no cracks, porous or cavities, no slag or nonmetal inclusions.

No further sample preparation is required. The sample is placed into a sample cartridge and then into spectrometer. Analysis is fulfilled automatically with a chosen program and prepared calibration curve.

Small size specimens or irregular shape specimens can be analyzed with fundamental parameters method.(standardless analysis method). In the latter case no calibration samples are required, but the accuracy of analysis is a little bit worse.

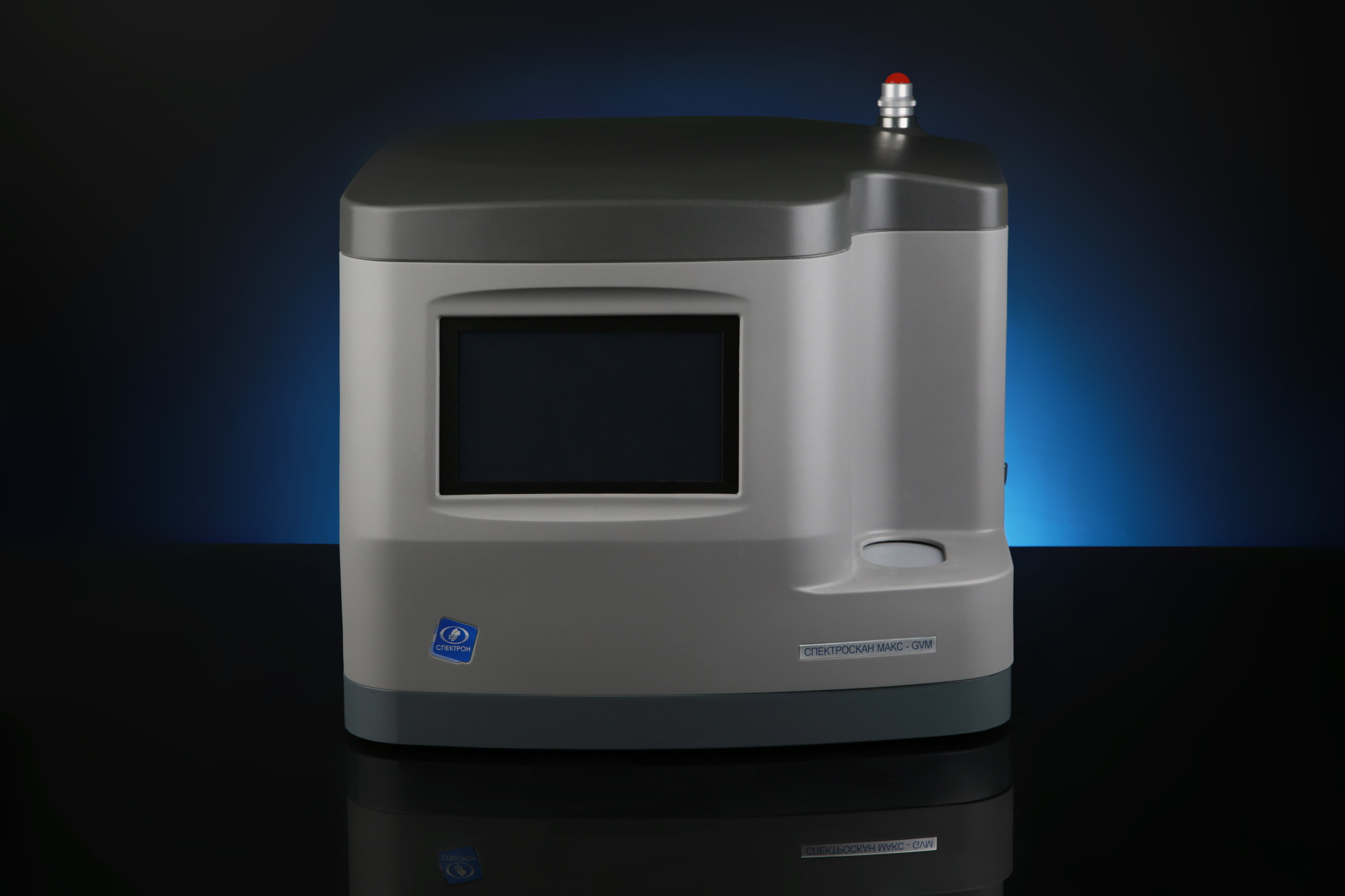

"SPECTROSCAN MAKC-GVM" WDXRF spectrometer determines elements from Na (Sodium) to U (Uranium) in solids, liquids or powders, in solutions and thin films, deposits on filters.

More »