Slack and refuse analysis

The major volume of slag generation is by ferrous and nonferrous metallurgy. The slags and tailings are used for additional metal extraction, construction material production, cement and fertilizers production, etc. Chemical composition of slag depends on the steel mark, composition of ore and flux. Usually slag contains from 35 to 47% of silicone oxide, 9-16% of aluminum oxide, 30-50% of calcium oxide, 2-14% of magnesium oxide, about 3% of manganese oxide and about 0.7% of iron. Nonferrous metallurgy slag contains oxides of copper, cobalt, nickel, zinc, lead, cadmium and rear metals besides mentioned above components.

One of the most interesting types of waste treatment is fertilizers production residual processing. Apatite and phosphorite are used for phosphorus fertilizers production. They contain some amount of rare earth elements. The residual is phosphorus gypsum containing up to 5 kg of rare metals per one ton of waste. Such concentration makes its processing profitable. Phosphorus gypsum application in cement industry and road construction is economically and ecologically reasonable.

X-ray fluorescence analysis is convenient for useful elements concentration determination while waste treatment. The greatest advantage is simple sample preparation. Express analysis supports permanent monitoring and control of the waste prqcessing.

One of the most interesting types of waste treatment is fertilizers production residual processing. Apatite and phosphorite are used for phosphorus fertilizers production. They contain some amount of rare earth elements. The residual is phosphorus gypsum containing up to 5 kg of rare metals per one ton of waste. Such concentration makes its processing profitable. Phosphorus gypsum application in cement industry and road construction is economically and ecologically reasonable.

X-ray fluorescence analysis is convenient for useful elements concentration determination while waste treatment. The greatest advantage is simple sample preparation. Express analysis supports permanent monitoring and control of the waste prqcessing.

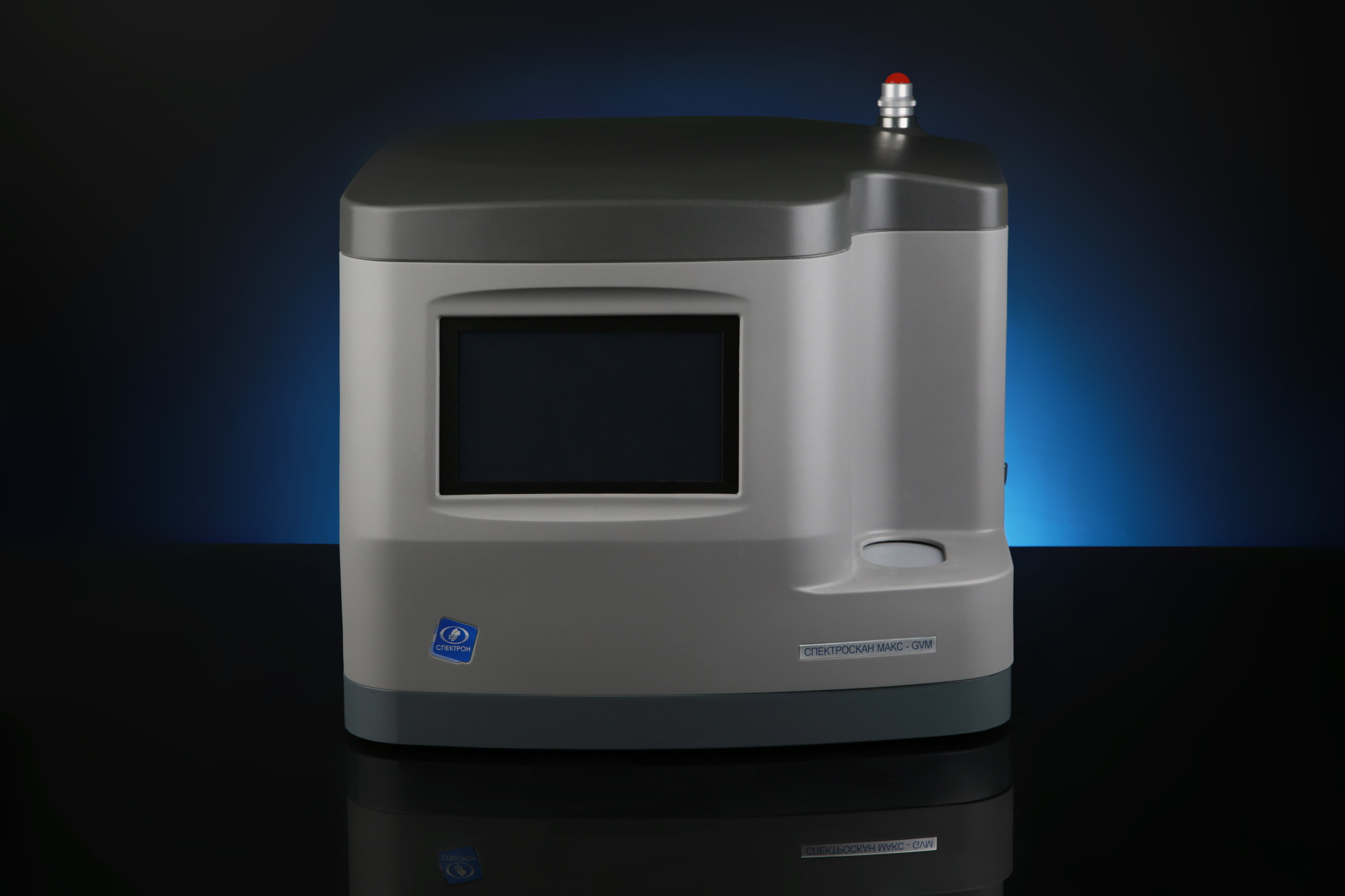

"SPECTROSCAN MAKC-GVM" WDXRF spectrometer determines elements from Na (Sodium) to U (Uranium) in solids, liquids or powders, in solutions and thin films, deposits on filters.

More »