Ceramics and refractory analysis

X-ray fluorescence method has advantages compared to other chemical and physical methods: sample analysis without its decomposition, selectivity, express analysis, wide range of element determination.

Ceramics and refractory can be analyzed with XRF method with minimal sample preparation. That is material grinding to the particle size of 50 micron with further pellets pressing. Prepared samples are placed in a spectrometer, and analyzed. Element content is calculated with preliminary obtained calibration curves.

There is another sample preparation method which provides significant improvement of metrological results – that is fusing the sample material with borate flux.

The test method specifies determination of Na2O, MgO, Al2O3, SiO2, P2O5, SO3, K2O, CaO, TiO2, Cr2O3, Mn3O4, Fe2O3, Co3O4, NiO, ZrO2, WO3, BaO, SrO, HfO2, HfO2, Y2O3, CeO2, La2O3, SnO2 in the concentration range from 0.01% up to 100%.

Fused samples provide better accuracy and reproducibility, but there are a lot of cases when pressed pellets are quite sufficient.

X-Ray fluorescence method provides rapid determination of a large number of components in a wide range of concentrations in ceramics and refractory without sample extraction. Sample preparation is either pressing or fusing the sample material dependent on the task.

Ceramics and refractory can be analyzed with XRF method with minimal sample preparation. That is material grinding to the particle size of 50 micron with further pellets pressing. Prepared samples are placed in a spectrometer, and analyzed. Element content is calculated with preliminary obtained calibration curves.

There is another sample preparation method which provides significant improvement of metrological results – that is fusing the sample material with borate flux.

The test method specifies determination of Na2O, MgO, Al2O3, SiO2, P2O5, SO3, K2O, CaO, TiO2, Cr2O3, Mn3O4, Fe2O3, Co3O4, NiO, ZrO2, WO3, BaO, SrO, HfO2, HfO2, Y2O3, CeO2, La2O3, SnO2 in the concentration range from 0.01% up to 100%.

Fused samples provide better accuracy and reproducibility, but there are a lot of cases when pressed pellets are quite sufficient.

X-Ray fluorescence method provides rapid determination of a large number of components in a wide range of concentrations in ceramics and refractory without sample extraction. Sample preparation is either pressing or fusing the sample material dependent on the task.

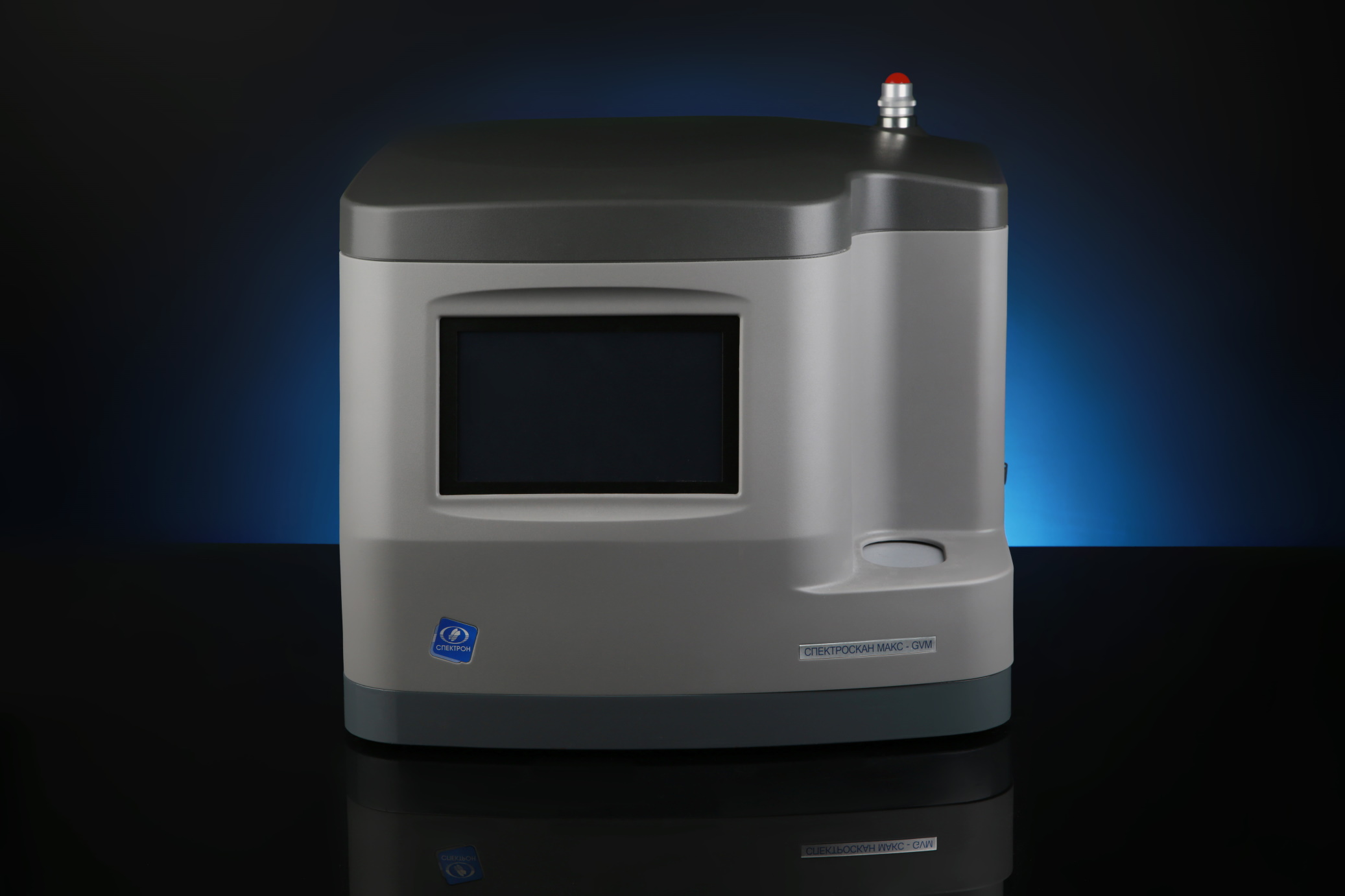

"SPECTROSCAN MAKC-GVM" WDXRF spectrometer determines elements from Na (Sodium) to U (Uranium) in solids, liquids or powders, in solutions and thin films, deposits on filters.

More »